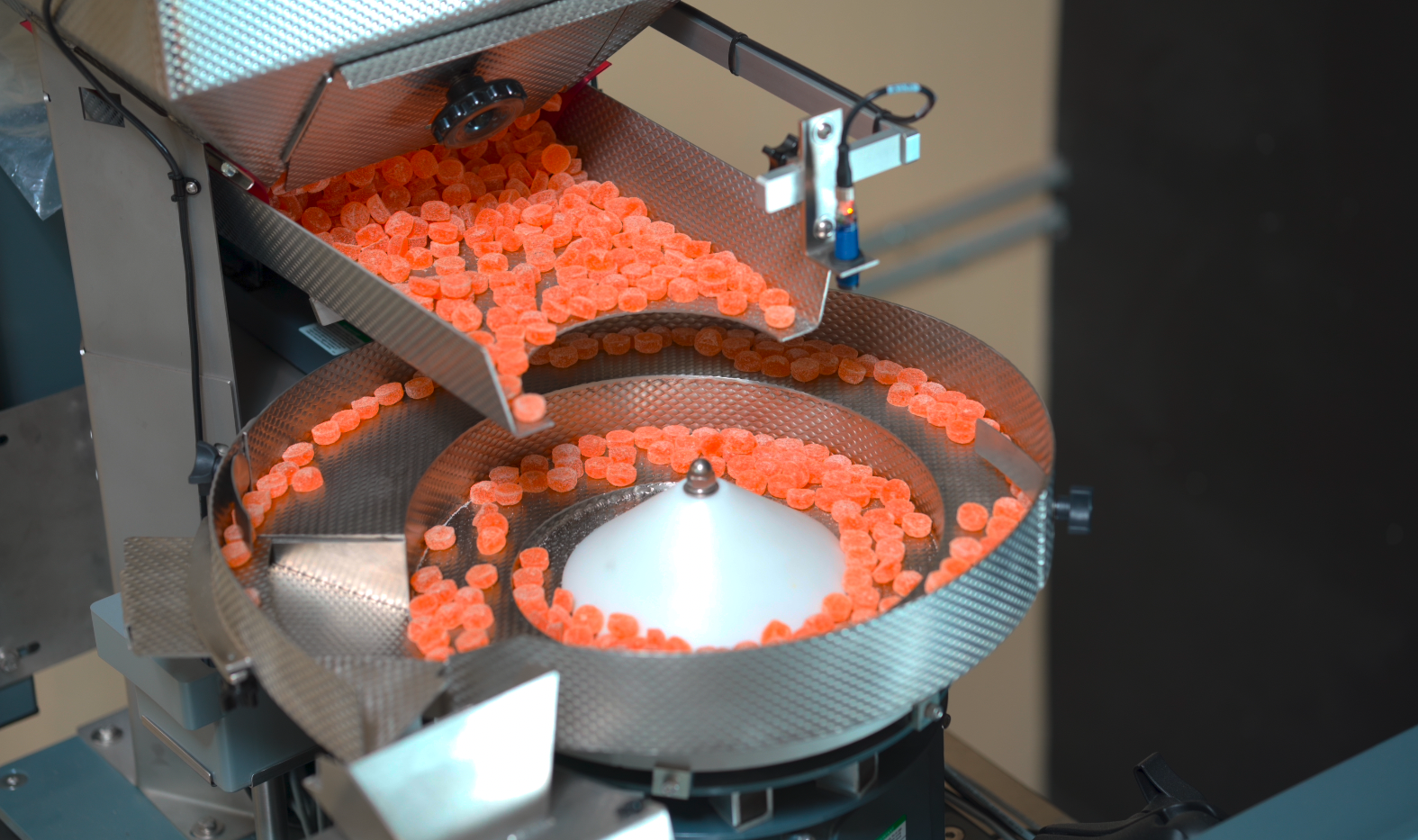

PrimoCount

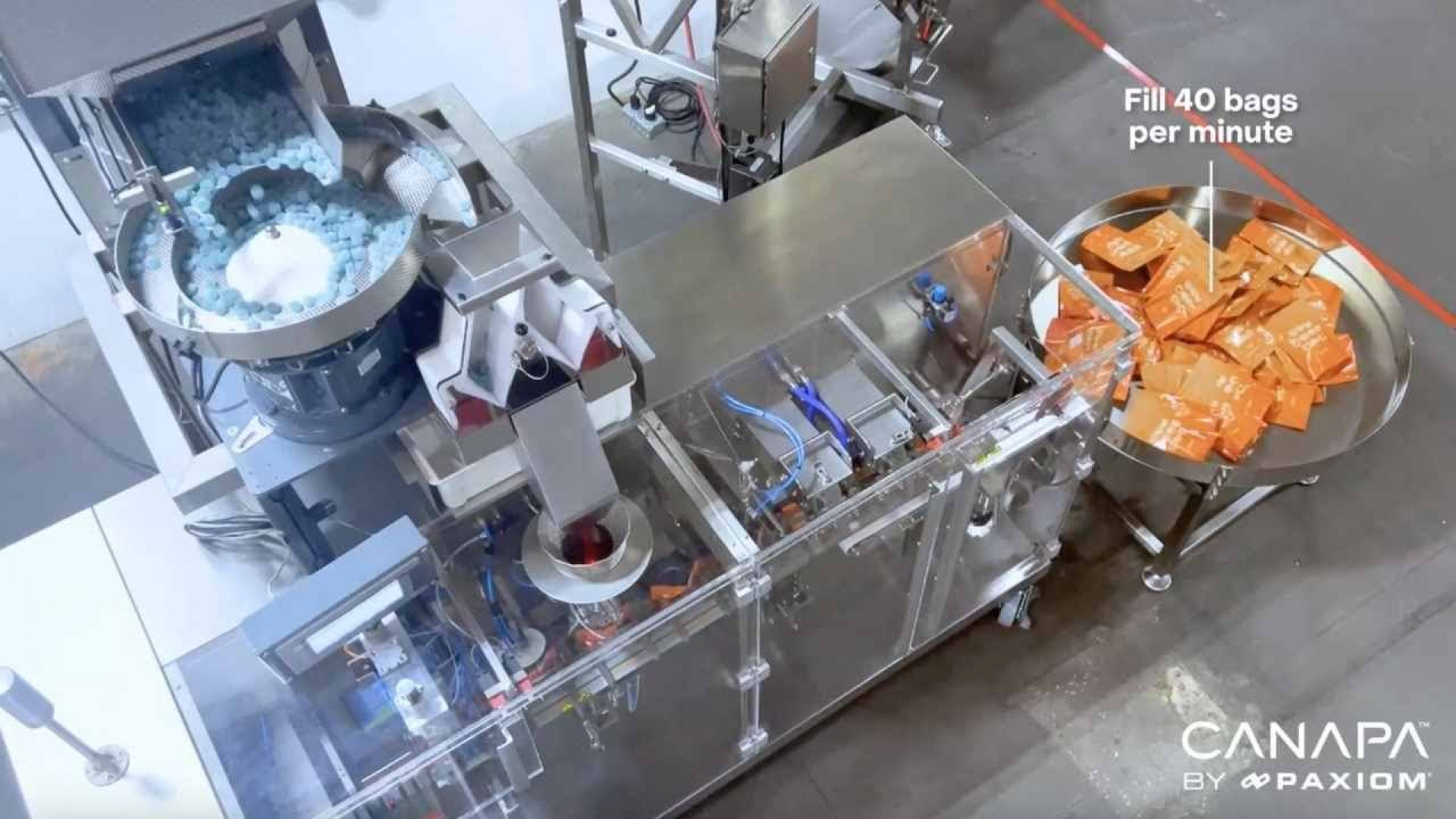

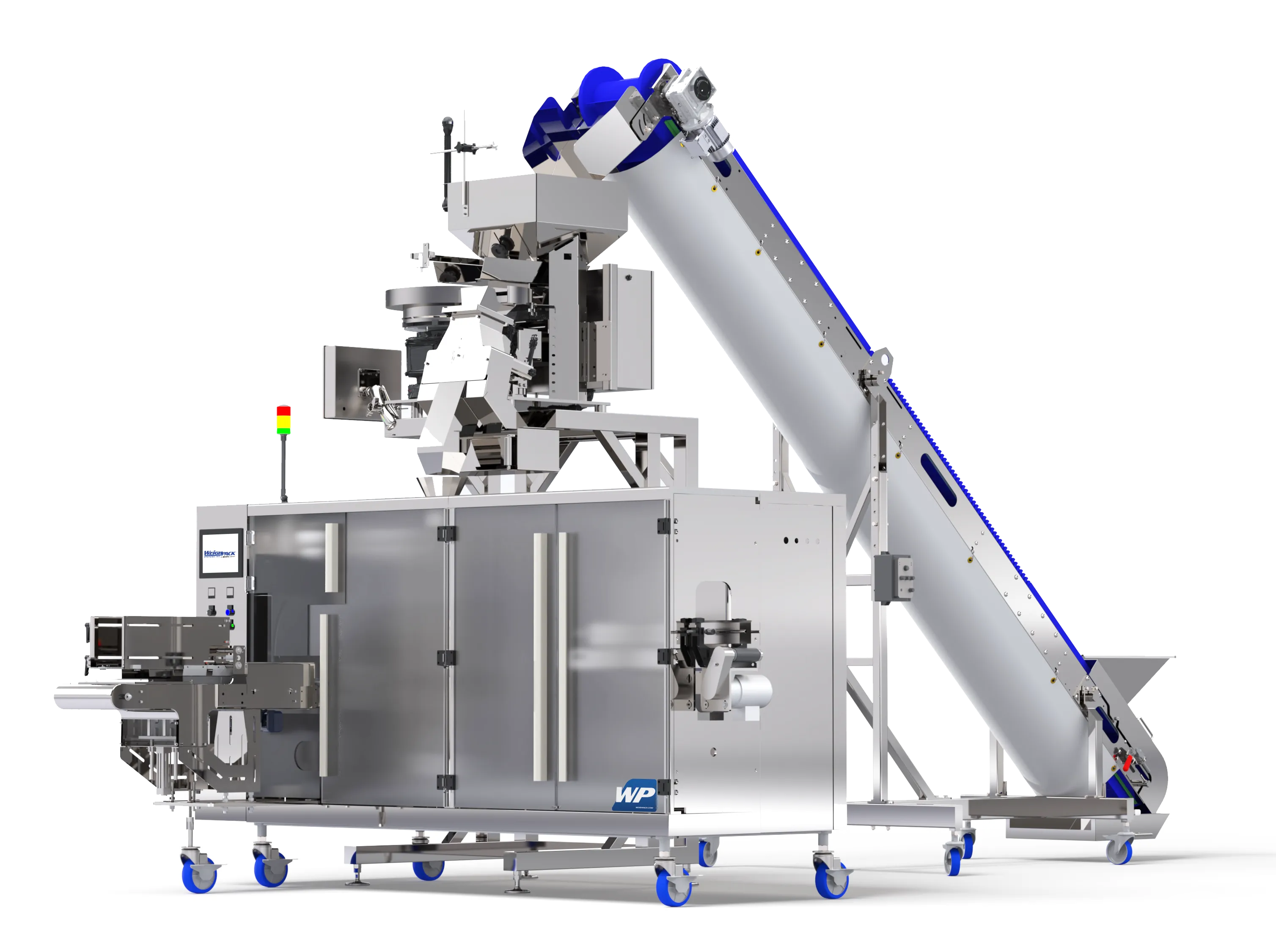

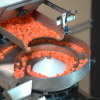

OPTICAL COUNTING BOWL FEEDER

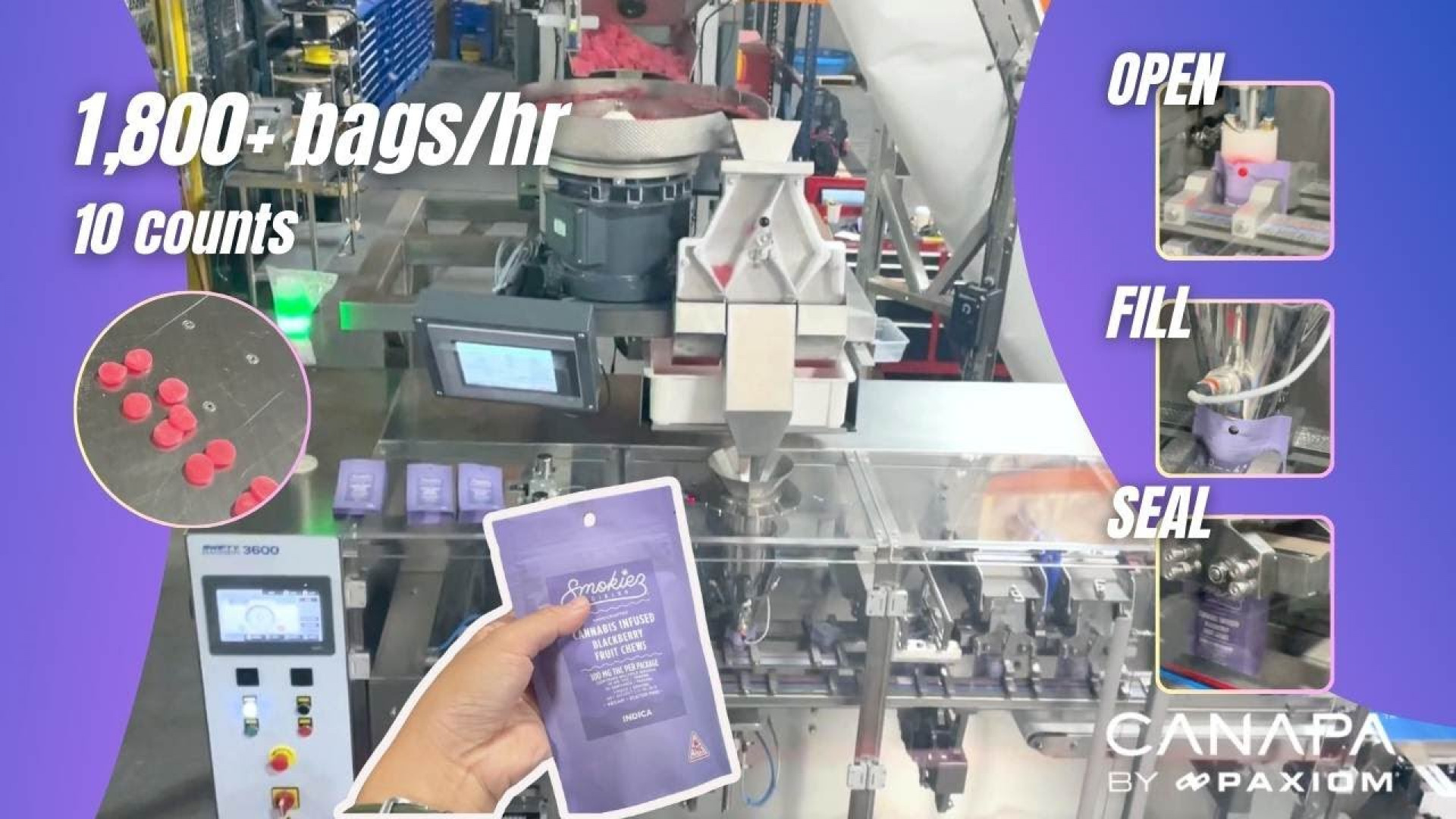

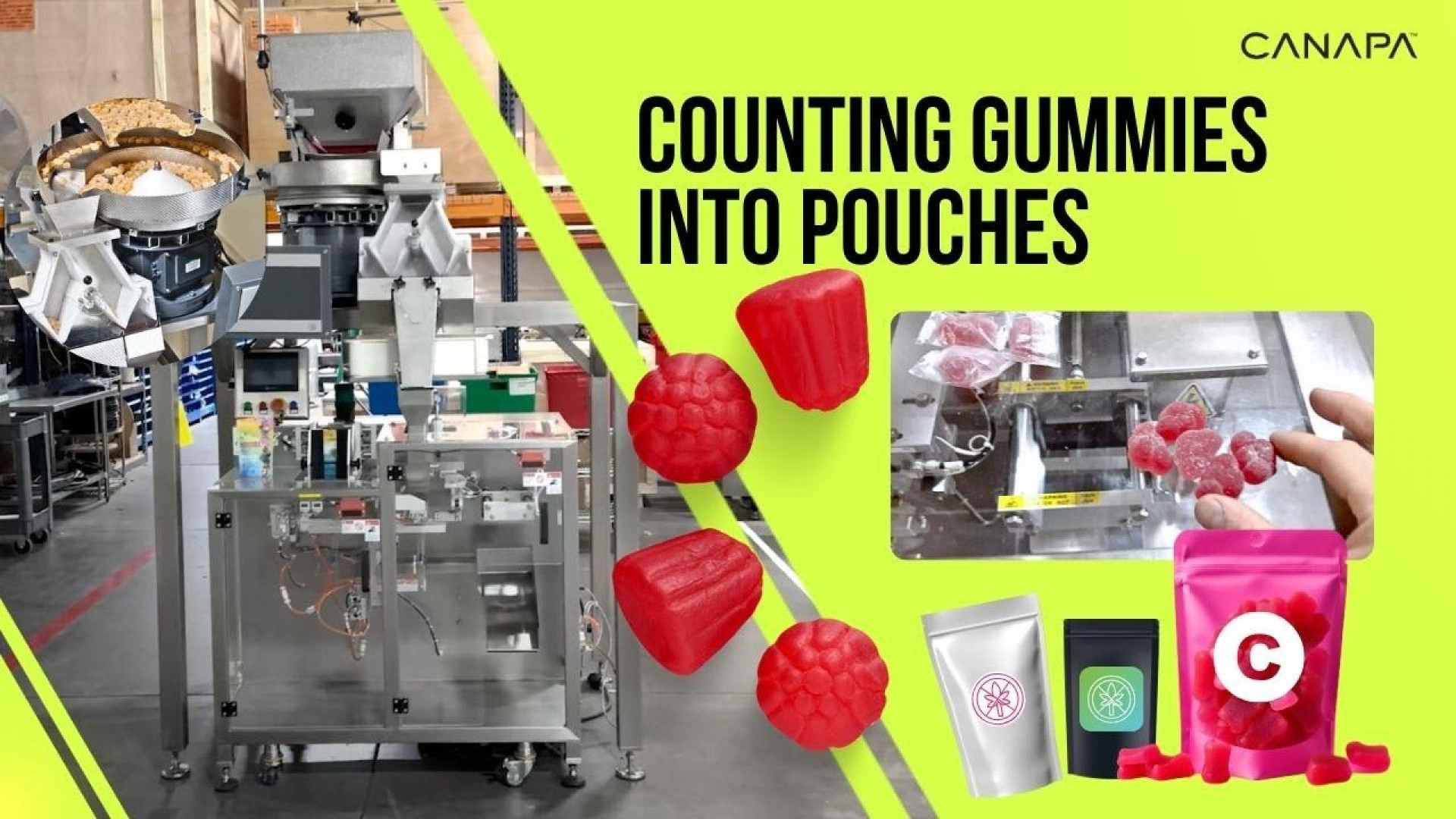

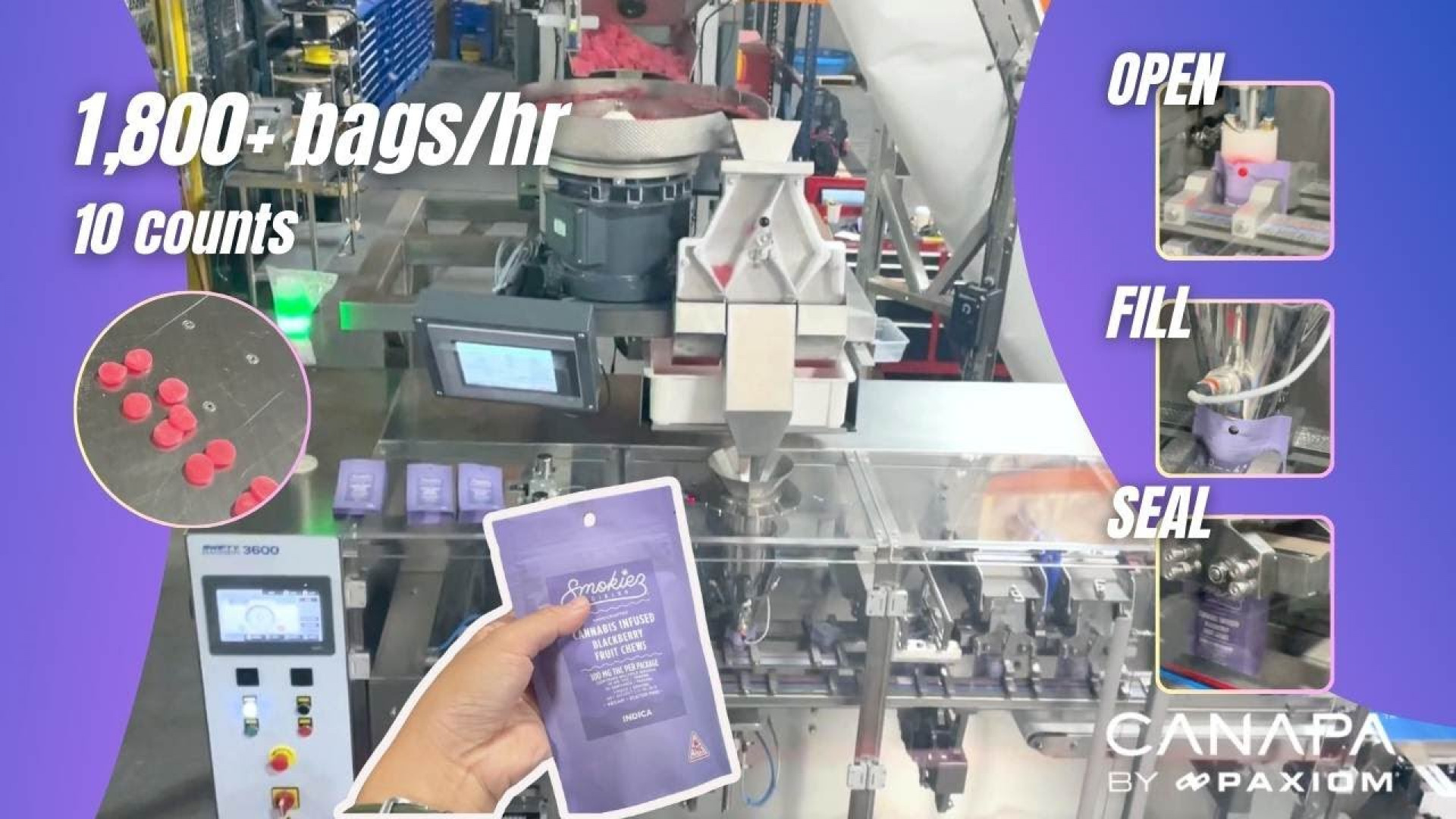

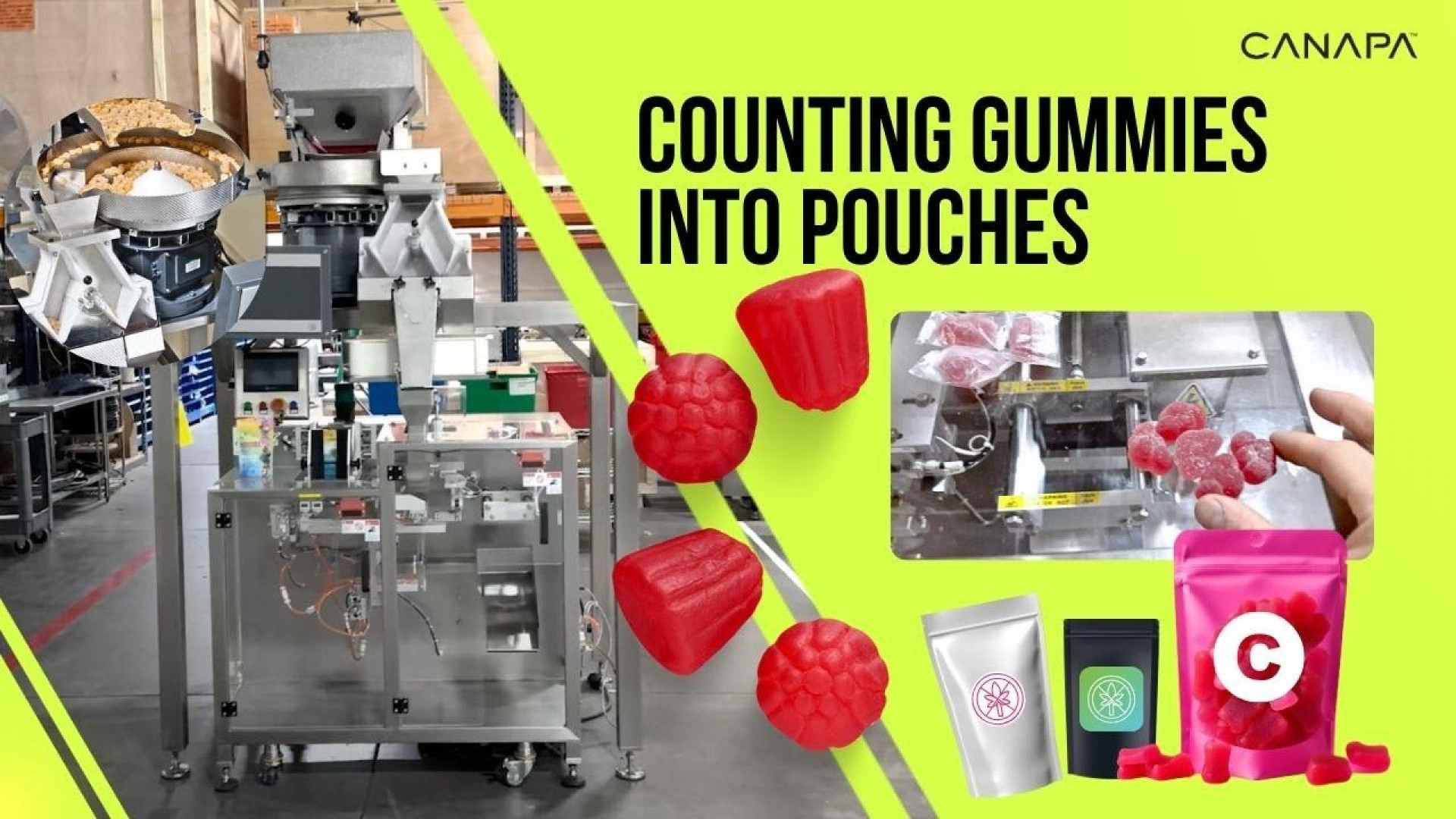

The PrimoCount is the only counter that utilizes patented dual view scanners that provide the highest

accuracy count possible. Continuous counting is performed while out of tolerance parts are rejected prior to entering a package.

Excellent for filling by count gummies, chocolates, edibles and wrapped products.

Videos

Features

- Auto Gate Fault Re-Start

- Auto Set-Up

- Bar Code Reading

- Closed Loop Stepper Motor Driven Gates

- Continuous Run, See Through Operation

- Custom Password Lock Outs

- Enhanced Geometry Dual Axis Feeder

- Food Grade and Anti-Static Options

- High Resolution with 6,000 Scans per Second

- Improved Auto-Calibration and Dust Filtering

- Industrial Grade Stainless Steel Bowl, Hopper & Stand

- In-Flight Volume Analysis

- Large 10.4” Color Touch Screen HMI Controls

- Multi-Chamber Part Processor

- Multiple Dump Feature

- Out of Tolerance Batch Reject

- Partial Accumulation and Split Counts

- Patented Dual View Scanner with Part Validation

- Real Time Operational Data

- Recipe Management

- State Of The Art High Speed Electronics

- Storable Set-Up Parameters of 500 Recipes

- Tool-Less Assembly / Disassembly & Changeover

- User Friendly Intuitive Set-Up

- Variable Electronic Tuning To Run a Wide Range of Parts

- Verified Motion Control Technology

Infused/CBD gummies

Infused/CBD candies

-

Specifications

-

Features

- Auto Gate Fault Re-Start

- Auto Set-Up

- Bar Code Reading

- Closed Loop Stepper Motor Driven Gates

- Continuous Run, See Through Operation

- Custom Password Lock Outs

- Enhanced Geometry Dual Axis Feeder

- Food Grade and Anti-Static Options

- High Resolution with 6,000 Scans per Second

- Improved Auto-Calibration and Dust Filtering

- Industrial Grade Stainless Steel Bowl, Hopper & Stand

- In-Flight Volume Analysis

- Large 10.4” Color Touch Screen HMI Controls

- Multi-Chamber Part Processor

- Multiple Dump Feature

- Out of Tolerance Batch Reject

- Partial Accumulation and Split Counts

- Patented Dual View Scanner with Part Validation

- Real Time Operational Data

- Recipe Management

- State Of The Art High Speed Electronics

- Storable Set-Up Parameters of 500 Recipes

- Tool-Less Assembly / Disassembly & Changeover

- User Friendly Intuitive Set-Up

- Variable Electronic Tuning To Run a Wide Range of Parts

- Verified Motion Control Technology

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD candies

We’re here to help

Want to see your product run on this machine?

PrimoCount

OPTICAL COUNTING BOWL FEEDER

Videos

The PrimoCount is the only counter that utilizes patented dual view scanners that provide the highest

accuracy count possible. Continuous counting is performed while out of tolerance parts are rejected prior to entering a package.

Features

- Auto Gate Fault Re-Start

- Auto Set-Up

- Bar Code Reading

- Closed Loop Stepper Motor Driven Gates

- Continuous Run, See Through Operation

- Custom Password Lock Outs

- Enhanced Geometry Dual Axis Feeder

- Food Grade and Anti-Static Options

- High Resolution with 6,000 Scans per Second

- Improved Auto-Calibration and Dust Filtering

- Industrial Grade Stainless Steel Bowl, Hopper & Stand

- In-Flight Volume Analysis

- Large 10.4” Color Touch Screen HMI Controls

- Multi-Chamber Part Processor

- Multiple Dump Feature

- Out of Tolerance Batch Reject

- Partial Accumulation and Split Counts

- Patented Dual View Scanner with Part Validation

- Real Time Operational Data

- Recipe Management

- State Of The Art High Speed Electronics

- Storable Set-Up Parameters of 500 Recipes

- Tool-Less Assembly / Disassembly & Changeover

- User Friendly Intuitive Set-Up

- Variable Electronic Tuning To Run a Wide Range of Parts

- Verified Motion Control Technology

Infused/CBD gummies

Infused/CBD candies

-

Specifications

-

Features

- Auto Gate Fault Re-Start

- Auto Set-Up

- Bar Code Reading

- Closed Loop Stepper Motor Driven Gates

- Continuous Run, See Through Operation

- Custom Password Lock Outs

- Enhanced Geometry Dual Axis Feeder

- Food Grade and Anti-Static Options

- High Resolution with 6,000 Scans per Second

- Improved Auto-Calibration and Dust Filtering

- Industrial Grade Stainless Steel Bowl, Hopper & Stand

- In-Flight Volume Analysis

- Large 10.4” Color Touch Screen HMI Controls

- Multi-Chamber Part Processor

- Multiple Dump Feature

- Out of Tolerance Batch Reject

- Partial Accumulation and Split Counts

- Patented Dual View Scanner with Part Validation

- Real Time Operational Data

- Recipe Management

- State Of The Art High Speed Electronics

- Storable Set-Up Parameters of 500 Recipes

- Tool-Less Assembly / Disassembly & Changeover

- User Friendly Intuitive Set-Up

- Variable Electronic Tuning To Run a Wide Range of Parts

- Verified Motion Control Technology

-

Ideal Products

-

Infused/CBD gummies

Infused/CBD candies