We’ve been fortunate to have supplied automated packaging machines to companies in the cannabis industry for nearly a decade. We understand the needs of our clients because we have grown with them and built a reputation for providing innovative, reliable solutions for their cannabis and hemp products.

We’ve helped clients bag their flower, jar their gummies, wrap their edibles and even developed customized solutions for their CBD products. From start-up companies to the largest multi-state operators, we are known for helping companies like yours meet growing demand while reducing product waste and saving resources.

Maybe you already have a weigh filling machine, but you haven’t yet automated the bagging process. Or maybe you’re looking into getting your first flow wrapper.

Whatever your situation, before you move forward, investigate the many benefits of a fully automated packaging system.

Why a System?

Consider this example.

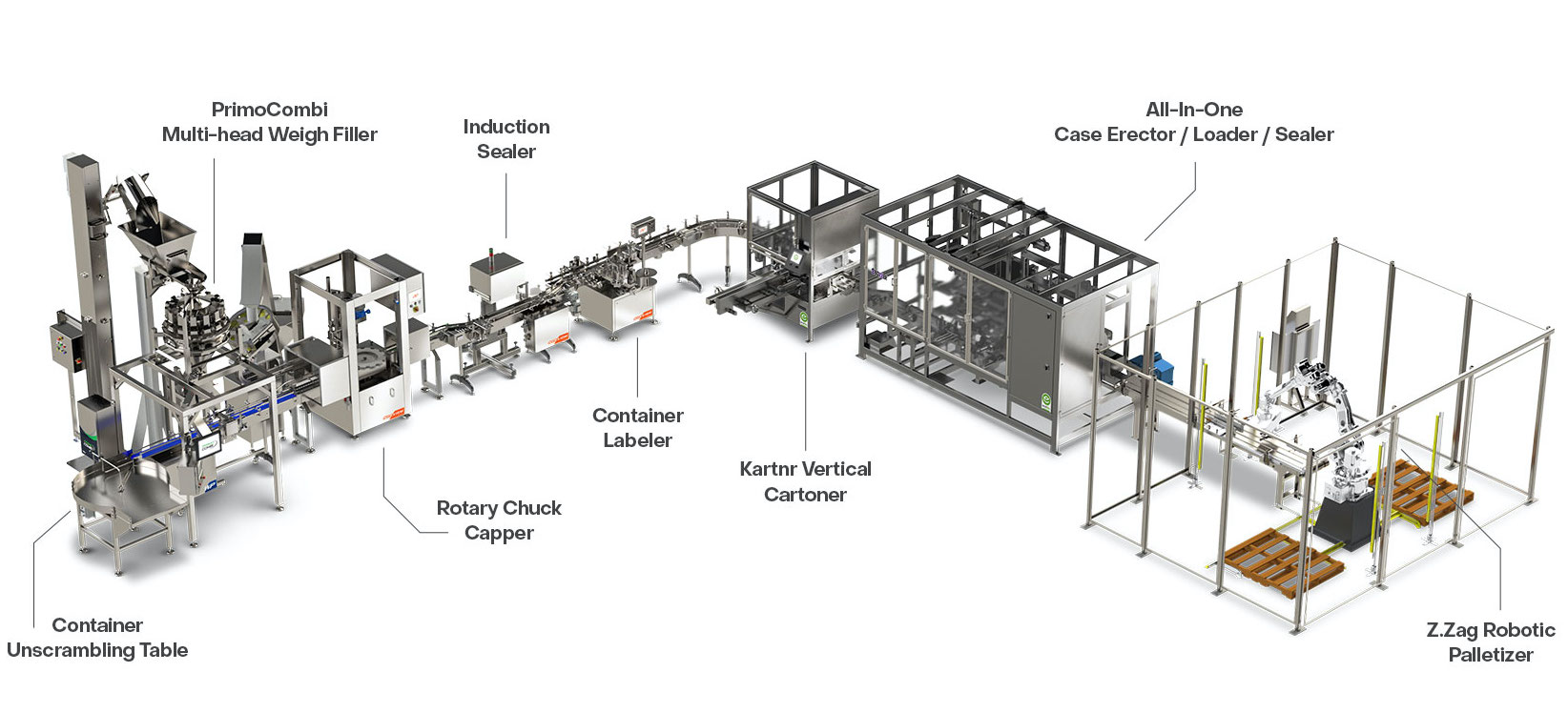

Let’s say you need to get your gummies into a container and then get that container into your nicely designed retail carton. That sounds simple, but you still need to cap, seal and label the container and then form, fill and close the carton.

You’re going to need some amount of automation for sure. You could probably argue that some of these stages could be done by hand. Ok then, let’s look a little deeper.

Let’s assume:

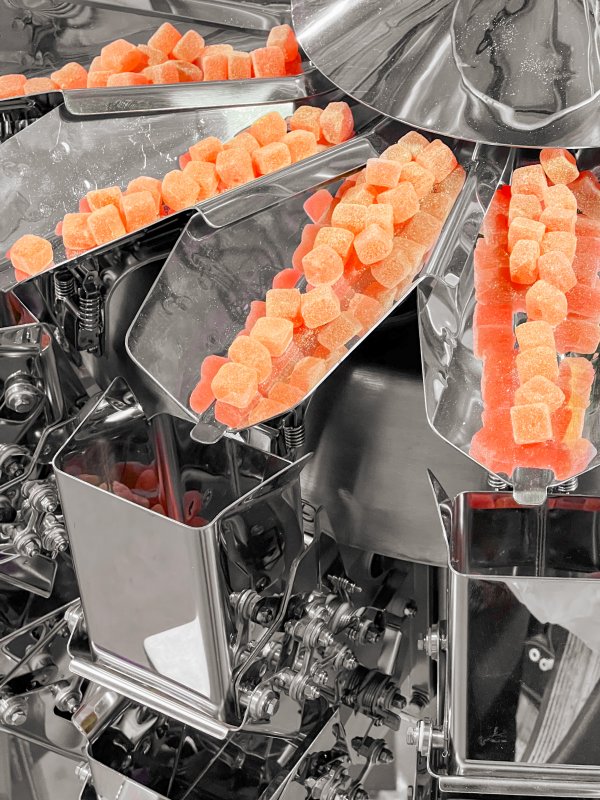

1) Dispensing too many gummies into each container costs you money and you would rather not risk product contamination. Result: you will need a weigh filling machine.

2) Having someone hold each container under the weigh filler and manually twist the cap on it could work but would take a lot of time. Result: you will need to accumulate the containers, convey them under the filling system and pass them through a capping machine.

3) That trying to have an employee manually seal a container is plain crazy. Result: You need an induction sealer.

4) Crooked, creased labels on a container look unprofessional, and placing them manually takes a ton of time. Result: you will need a labeling machine.

5) Your carton is way too important to your retail presence to trust to a manual forming, loading and closing process (and also time-consuming). Result: you need an automated cartoner.

Conclusion: a fully integrated container filling and handling system is the most efficient way to get your gummies ready for retail. And while it might sound costly on the front end, what is the cost on the backend in product waste and the loss of hundreds of worker hours?

One last thought…what happens to your cartons after they’re closed? Do you need to get them into cases and then ship those cases to your other locations?

If you want to save yourself even more time and reduce repetitive worker injury, we can add our all-in-one case erector/loader/sealer and our robotic palletizer after the cartoning process.

That means you only need one person to place containers on the initial accumulation table and one person to come and pick up your pallet full of sealed cases for shipment.

Make It Happen

Whether it’s this scenario or some other custom cannabis or hemp application you need, we can help. We do it for companies large and small every day. We will evaluate your current packaging process and design a system that works within your budget and production requirements.

Leading LPs across the Unites States and Canada have trusted us to be their partner for a reason. But don’t just take our word for it. Reach out today and we will happily provide you with client references so you can ask them yourself.

And when you’re ready, we would be honored to have you come to our Flagship Xperience Center in Las Vegas to see our solutions in person.