Maximizing Quality and Consistency with Automated Pre Roll Machines

The cannabis industry is growing and pre rolls are leading the charge. Headset.io estimates that pre rolls will make up 20% of cannabis industry sales by 2030—just a few years away!

As consumer demand grows, smart producers are turning to automation to increase output, but pre roll machines do more than just speed up the process. The best technology can improve quality and consistency at the same time, which is just as important.

Let’s look at why producers need to be thinking hard about quality and consistency, the benefits of automation, and how the latest technology can keep your brand in the industry.

The Importance of Pre Roll Quality

Pre-rolls are no longer new to cannabis consumers, which means the market is maturing and users are looking for more than novelty and convenience. People are tuned into quality, and they want the best.

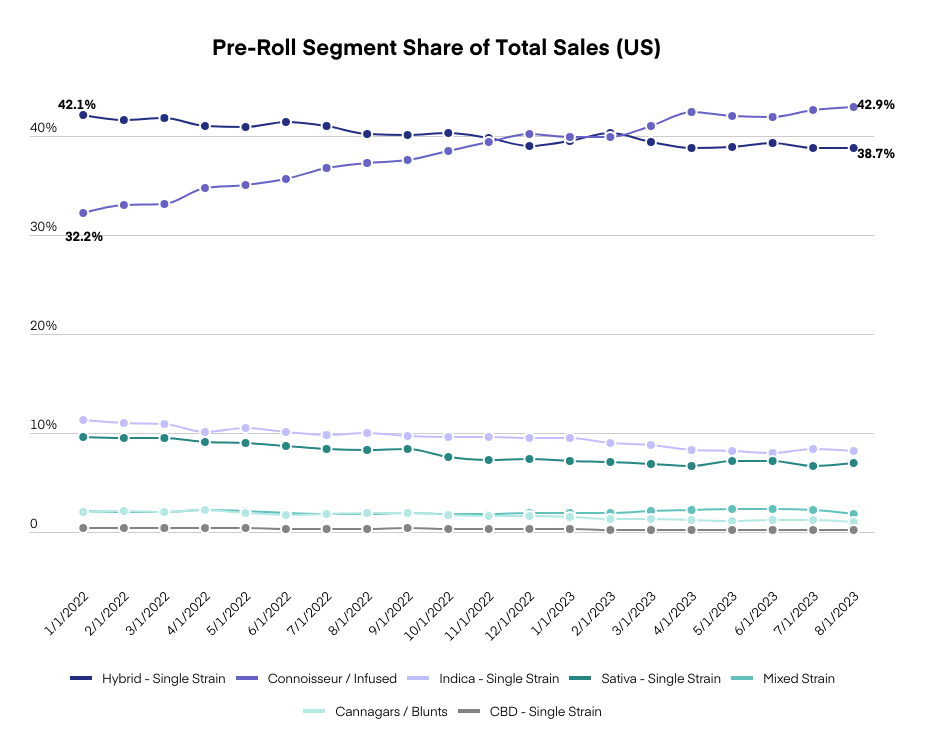

In fact, the most popular type of pre rolls are “connoisseur / infused” varieties, which recently started to outperform the other big winner: “hybrid-single strain.”

There is a clear preference among cannabis users for the very best pre rolls.

How are they judging the joints they purchase? Buyers routinely consider characteristics like:

- Single strain vs. mixed

- Whole flowers vs. shake

- Cone length

- Cone color

- Cone shape

- Twist tightness and length

Producing top-quality pre rolls is crucial to staying in the cannabis industry. Pre-rolls are the fastest-growing segment of this business, so brands have to get it right.

The Importance of Pre Roll Consistency

High-quality production capabilities are meaningless if that quality isn’t consistent. One bent, skimpy, or broken joint is enough to shatter customer trust and loyalty. Because that user doesn’t see 5,000 other perfect pre-rolls—just the one bad one that ruined their evening (and possibly their friends’ evenings … and maybe part of their reputation).

It’s enough to lose a customer—or a room full of customers.

- At least 57% of consumers will abandon a brand after just one bad experience.

- The #1 reason that consumers are loyal to a brand is, “The products or services are high quality, reliable, and consistent.”

It may not seem fair that one low-quality joint can undo the positive impression created by dozens of other great ones … but that’s how it is.

Once the consistency is broken, people don’t want to risk it happening again. In the fastest growing product segment of the cannabis industry, users have a lot of other brands to choose from.

Maximizing Quality and Consistency with Automation

The good news is that there’s a simple solution for producing the very best pre rolls with the highest possible rate of consistency: automation.

Automated pre-roll machines are the cause and the effect of the rising popularity of pre rolls in the industry. As more cannabis brands embrace automation, more top-quality joints hit the market, and users have come to learn they can trust at least some brands to create a great, consistent product experience.

With increasing consumer demand, more brands are investing in pre roll automation to stay competitive.

Benefits of Pre Roll Automation

There is a range of automation capabilities available, but the very best pre roll machines offer additional benefits, beyond consistent quality:

- Increased productivity: Pre roll machines can accomplish the otherwise impossible task of improving quality, consistency, and output. Industry-leading automation can produce up to 4,000 high-quality joints per hour.

- Big cost-savings: Pre roll machines require very light maintenance and little input from human operators. Producing a greater number of excellent pre rolls, with no additional recurring overhead, means you increase ROI.

- Greater efficiency: Taken together, pre roll automation is the best solution for improving efficiencies in the cannabis industry. When your production process is efficient, you can spend time on other things.

Automated pre roll machines are no longer the future of the cannabis industry: they’re leading the field today.

How Automation Improves Pre Roll Quality, Consistently

Whether you’re using semi-automatic pre roll weigh and fill stations, or fully automatic pre roll machines, the robotics and technology are among the most advanced and fine-tuned across any industry.

1. Weight Checking Technology

Making sure each pre-roll is consistent starts with how well it’s packed, but joints are much too small and light for standard scales.

That’s why the best check weigher machines use electromagnetic force restoration (EMFR) weigh cell technology. EMFR is so accurate, it’s the standard used in pharmaceutical, jewelry, and aerospace industries. It relies on precise electronic measurements that are not affected by external influences.

The weight technology in industry-leading pre roll automation is accurate to within 0.01 gram. That kind of specificity enables your brand to produce uniform consistency with every joint.

2. Visual Inspection Technology

Chefs know that people “eat with their eyes first”—meaning visual cues impact how people perceive and interact with consumable products. Every pre roll needs to look like the best possible experience even before the tail is lit.

Sophisticated pre-roll automation uses multiple high-quality cameras to get a 360-degree view of every product. A good visual inspection system should be able to check for:

- Tail length

- Fill length

- Holes or damaged paper

- Filter length

- Cone color

- Shape

Pre-Roll Quality FAQs

Are pre-rolls good quality?

Yes. Most pre rolls sold on the market since legalization started are good, quality cannabis products. That consistent quality is largely thanks to more and more companies embracing automation for production.

How do you know if a pre roll is good?

First, check the package: A good pre roll is made from a single strain of whole, high-quality or connoisseur flowers. The second indicator of a good pre roll is a simple visual inspection. Make sure the cone is straight, the paper is not ripped, and the tail is twisted to a good length.

Why are pre-rolls so cheap?

Pre rolls are increasingly affordable, because leading producers have adopted high tech automation systems. Pre roll machines can produce thousands of joints per hour. That efficiency allows them to sell even the best strains for very affordable prices.

Start Perfecting Your Pre-Rolls Today

The truth is, there’s no reason not to invest in pre-roll automation anymore. The technology is outstanding, consumer demand is growing, and people’s expectations for quality and consistency is high.

Maybe the best part about a great pre-roll automation system is that you can start small if you need to. Start with a semi-automatic weight station or automate just the quality control steps. You can add on to the system incrementally.

If you’re not sure where to start, our packaging automation experts can help you figure it out. If you’re ready to get started, don’t waste another minute. Give us a call at 1.833.4PAXIOM or fill out our contact form and we’ll get your brand set up to make the most of this growing cannabis opportunity.