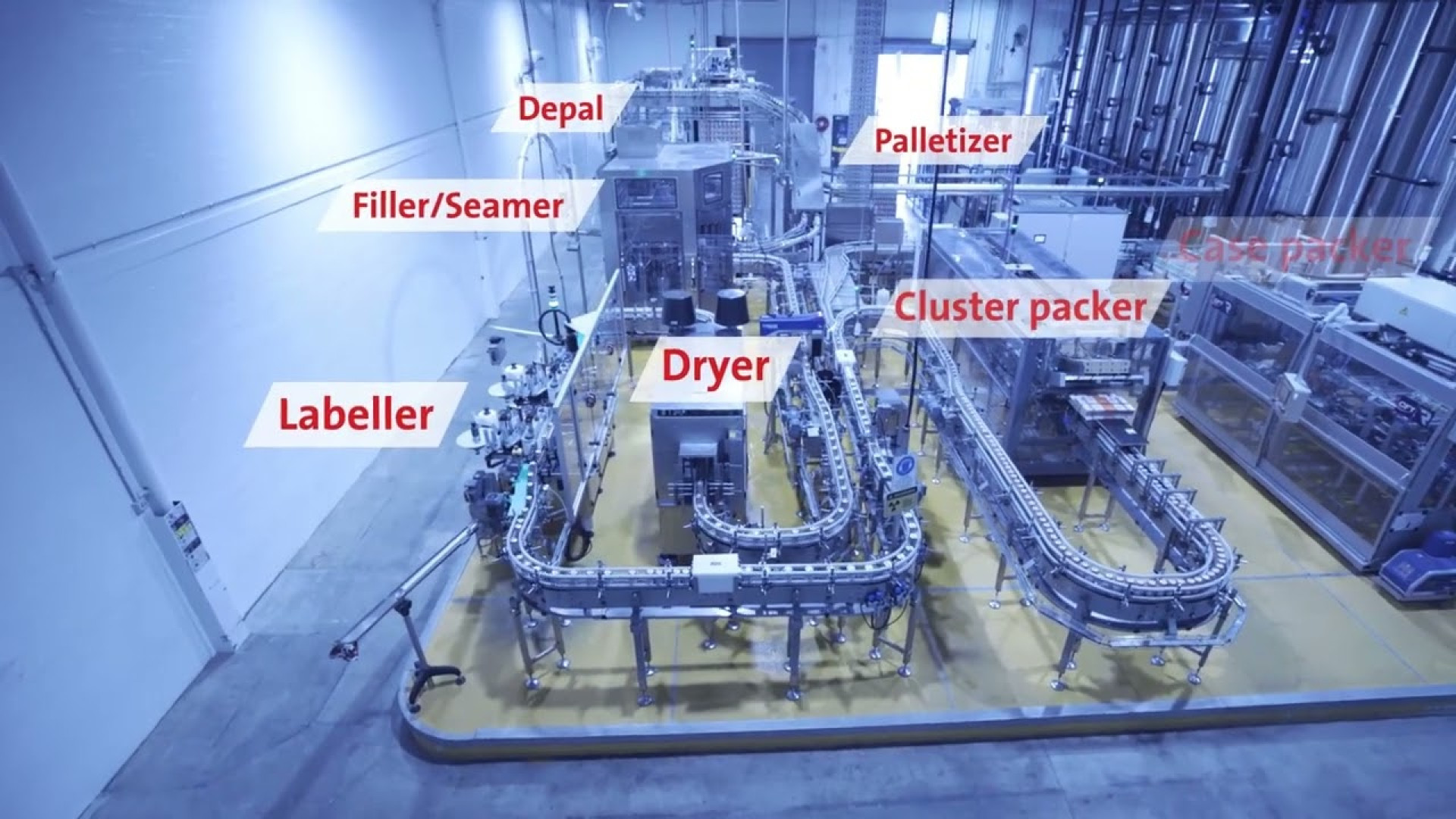

Co.Mac Pegasus

for complete beverage filling and packaging automation

The PEGASUS can filling/seaming machine is a versatile and efficient solution for medium/low capacity beverage production lines. Based on back-pressure filling technology, it’s ideal for filling still and carbonated beverages into aluminum cans.

Key Features:

- Back-Pressure Filling: Ensures precise filling levels and minimizes product loss by maintaining a positive pressure within the can during filling.

- CO2 Flushing: Effectively flushes cans with CO2 or other inert gases to prevent oxidation and maintain product freshness.

- Reliable Seaming: Equipped with a high-quality seamer from a leading industry manufacturer, guaranteeing consistent and secure can sealing.

- Electropneumatic Filling Valves: Offer precise control and durability for long-term, reliable operation.

- Compact Design: Efficiently utilizes floor space, making it suitable for various production environments.

By choosing the PEGASUS can filling/seaming machine, you’re investing in a reliable and efficient solution that will help you optimize your beverage production line and meet the demands of your market.

Formats

- Two-pieces aluminium cans, lids size from 200 to 209, volume from 200 ml to 1,000 ml

Videos

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

-

Ideal Products

-

CBD Beverages

THC Infused Beverages

We’re here to help

Want to see your product run on this machine?

Co.Mac Microbrew 10-2

FILLING AND CANNING SYSTEM

The Microbrew 10-2 is a compact and user-friendly canning line designed specifically for your needs. This monoblock system seamlessly integrates filling and seaming into one efficient machine, minimizing your footprint and maximizing production flexibility.

Equipped with electropneumatic filling valves and counter-pressure filling technology, the Microbrew 10-2 guarantees high-precision filling for both still and carbonated beverages.

This ensures minimal product loss and consistent quality in every can. Plus, the Microbrew 10-2 offers customizable settings for filling parameters like inert gas flushing, pressurization, and decompression. This allows you to tailor the canning process to your specific infused beverages, achieving optimal results for every unique brew.

Videos

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical filler

- Cans from 0.15L to 19,2oz (568ml)

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical filler

- Cans from 0.15L to 19,2oz (568ml)

-

Ideal Products

-

CBD Beverages

THC Infused Beverages

We’re here to help

Want to see your product run on this machine?

Co.Mac Microbrew 20-4

FILLING AND CANNING SYSTEM

Elevate your cannabis beverage brewing capabilities with the Microbrew 20-4-2, a compact and versatile canning line designed to streamline your production process. This monoblock system combines filling and seaming into a single, space-saving unit, maximizing efficiency without compromising on quality.

The Microbrew 20-4-2 utilizes electropneumatic filling valves and counter-pressure filling technology to ensure precise and consistent filling of both still and carbonated beverages. This minimizes product loss and guarantees consistent, high-quality results in every can. Furthermore, the machine boasts user-friendly controls that allow you to customize filling parameters, including inert gas flushing, pressurization, and decompression. This level of control empowers you to tailor the canning process to your specific infused beverages, ensuring optimal results for every unique brew you create.

Videos

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

- Cans from 0.15L to 19,2oz (568ml)

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

- Cans from 0.15L to 19,2oz (568ml)

-

Ideal Products

-

CBD Beverages

THC Infused Beverages

We’re here to help

Want to see your product run on this machine?

Co.Mac Pegasus

for complete beverage filling and packaging automation

Videos

The PEGASUS can filling/seaming machine is a versatile and efficient solution for medium/low capacity beverage production lines. Based on back-pressure filling technology, it’s ideal for filling still and carbonated beverages into aluminum cans.

Key Features:

- Back-Pressure Filling: Ensures precise filling levels and minimizes product loss by maintaining a positive pressure within the can during filling.

- CO2 Flushing: Effectively flushes cans with CO2 or other inert gases to prevent oxidation and maintain product freshness.

- Reliable Seaming: Equipped with a high-quality seamer from a leading industry manufacturer, guaranteeing consistent and secure can sealing.

- Electropneumatic Filling Valves: Offer precise control and durability for long-term, reliable operation.

- Compact Design: Efficiently utilizes floor space, making it suitable for various production environments.

By choosing the PEGASUS can filling/seaming machine, you’re investing in a reliable and efficient solution that will help you optimize your beverage production line and meet the demands of your market.

Formats

- Two-pieces aluminium cans, lids size from 200 to 209, volume from 200 ml to 1,000 ml

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

-

Ideal Products

-

CBD Beverages

THC Infused Beverages

Co.Mac Microbrew 10-2

FILLING AND CANNING SYSTEM

Videos

The Microbrew 10-2 is a compact and user-friendly canning line designed specifically for your needs. This monoblock system seamlessly integrates filling and seaming into one efficient machine, minimizing your footprint and maximizing production flexibility.

Equipped with electropneumatic filling valves and counter-pressure filling technology, the Microbrew 10-2 guarantees high-precision filling for both still and carbonated beverages.

This ensures minimal product loss and consistent quality in every can. Plus, the Microbrew 10-2 offers customizable settings for filling parameters like inert gas flushing, pressurization, and decompression. This allows you to tailor the canning process to your specific infused beverages, achieving optimal results for every unique brew.

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical filler

- Cans from 0.15L to 19,2oz (568ml)

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical filler

- Cans from 0.15L to 19,2oz (568ml)

-

Ideal Products

-

CBD Beverages

THC Infused Beverages

Co.Mac Microbrew 20-4

FILLING AND CANNING SYSTEM

Videos

Elevate your cannabis beverage brewing capabilities with the Microbrew 20-4-2, a compact and versatile canning line designed to streamline your production process. This monoblock system combines filling and seaming into a single, space-saving unit, maximizing efficiency without compromising on quality.

The Microbrew 20-4-2 utilizes electropneumatic filling valves and counter-pressure filling technology to ensure precise and consistent filling of both still and carbonated beverages. This minimizes product loss and guarantees consistent, high-quality results in every can. Furthermore, the machine boasts user-friendly controls that allow you to customize filling parameters, including inert gas flushing, pressurization, and decompression. This level of control empowers you to tailor the canning process to your specific infused beverages, ensuring optimal results for every unique brew you create.

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

- Cans from 0.15L to 19,2oz (568ml)

CBD Beverages

THC Infused Beverages

-

Specifications

-

Features:

- High performance according to the type of monoblock

- Quality of the finished product due to the use of the same technical solutions of high-capacity monoblocks

- Optimal settings for all filling parameters (inert gas flushing, pressurization, filling, decompression)

- Dedicated recipes for different types of products adjustable and selectable from HMI

- All filling parameters remain unchanged; They do not depend on the capacity of the machine, as for standard mechanical fillers

- Cans from 0.15L to 19,2oz (568ml)

-

Ideal Products

-

CBD Beverages

THC Infused Beverages